11111

2222

3333

Speak with one of our customer success representatives.

1-800-475-2235label.oneprint@gmail.com

Speak with one of our customer success representatives.

SDSADSADSADSA

DSADASDSAD

Start by choosing your label size, shape, and material. Then upload your logo, artwork, or message in our design system or work with our team to create something custom. We offer both small and bulk order options — whether you’re doing a product launch or a full production run, we’ve got you covered

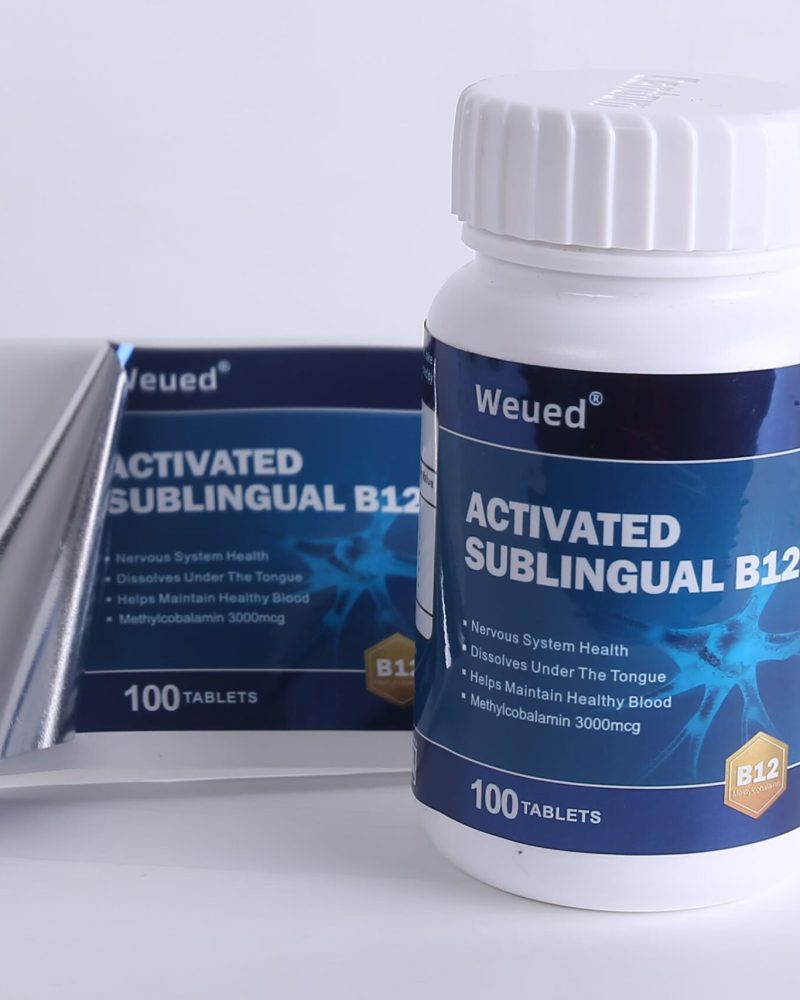

When it comes to product presentation and compliance, custom self-adhesive labels are a smart, cost-effective way to elevate your packaging. Whether you’re labeling health supplements, pharmaceuticals, wine bottles, or cartoon-themed products, our label solutions are designed to perform and impress. With vivid print quality and tailored design, your product becomes more than a package — it becomes a brand experience.

Our labels are made with high-quality adhesive and are compatible with glass, plastic, metal, and more. Available in paper or film materials, including matte, glossy, waterproof, oil-proof, and eco-friendly options. Backed with strong adhesive, they’re easy to peel, apply, and stay firmly in place even in challenging environments — like cold storage, moisture, or frequent handling.

These labels came out fantastic! I couldn’t be more pleased with the way my product looks wearing them.

Posted 1 months ago

Great service, product and people!

Posted 1 months ago

The Consolidated Label Co is easy to work with. As a business, we’ve used their labels repeatedly and keep going back to them based on the quality of labels provided and the outstanding service.

Posted 2 months ago

These labels came out fantastic! I couldn’t be more pleased with the way my product looks wearing them.

Posted 2 months ago

Bernice was absoluetly fabulous to work with. So helpful.

Posted 3 months ago

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Posted 3 months ago

An ‘eye mark’ (also known as ‘eye spot’) is a small rectangular printed area located near the edge of the printed flexible packaging material. A sensor on the form-fill-seal (FFS) machine reads the eye mark to identify packaging material, control the material’s position, and coordinate the separation and cutting of the flexible packaging material. To package products with flexible packaging, the printed material is supplied on a continuous roll and fed into the FFS machine where the sensor reads the eye mark to indicate when to cut individual units, fold the material, seal the sides (creating the packaging’s shape), fill with the product, and then seal the final side. It’s important to note that the eye mark pathway should be clear of obstructing design or text to ensure the sensor reads it properly.

Mollis vel morbi lacinia quam vel, imperdiet id nec consectetuer sit volutpat, nunc massa egestas, luctus molestie. Libero metus consectetuer vel libero, est dignissim turpis viverra etiam, est bibendum cras hac, suscipit consequat sit orci pede. Eget fusce fermentum egestas, gravida amet sagittis. Hendrerit suspendisse, aliquam ut, quis purus.

Images on the Internet tend to have low image resolution so it’s essential that you use high-resolution images of at least 300 DPI (dots per inch) so the labels don’t look blurry when they’re printed. ‘Image resolution’ refers to how many ‘pixels’ make up an image will fit inside each inch of the printed photo area. More pixels per inch makes the image appear smaller on paper, while fewer pixels makes the image appear larger on paper. However, more pixels per inch means more detail is shown in your image. Image resolution is really only important when it comes to printing. In fact, most images you find on the internet are only 72 DPI which is enough detail to render a decent image on the screen but not nearly enough detail to print a quality image at full size. If you try to print a 72 dpi image at a larger size, the printed image will look blurry and won’t be usable.

Flexographic printing is a popular method for printing large orders of custom labels at rapid speeds by transferring ink onto the paper or film material using flexible printing plates mounted on fast-rotating cylinders. Flexographic printing plates allow customization options that aren’t possible with some other types of presses. A variety of products can be printed on flexographic presses like pressure-sensitive labels, shrink sleeve labels, flexible packets, multi-ply labels, double-sided printed labels, and more.

Pressure sensitive adhesives (aka ‘self-stick’ adhesives that don’t require solvents or heat to activate the adhesive) shouldn’t be used in the oven or microwave for a couple of reasons. When heated at high temperatures, the adhesive can melt and give off an odor. Adhesives have what’s known as a ‘service temperature range’ which refers to the temperature range the adhesive can function after the label has been applied and built up to its ultimate adhesion. Most pressure sensitive adhesives have a range of -65 °F to 200 °F with a paper label stock or up to 300 °F with a film label stock.

Temperature is an important consideration with labels because extreme heat or cold affect label quality. For more information, please check out our pressure sensitive adhesive guide. If you have technical requirements to consider or just want to make sure the material you want will work for your project, our customer service team would be happy to help – call us at 1-800-475-2235 or email sales@consolidatedlabel.com.

When we get asked about the shelf life of labels, it’s important to distinguish these two concepts – shelf life and service life. Shelf life is the length of time that a label material may be stored without becoming unfit for use, whereas, the service life of a label material is the minimum length of time that a label will reliably stay fixed on a surface while being used for its intended purpose and exposed to typical conditions. Using a material past its shelf life could hinder print quality, adhesive performance, and general durability – a reliable label company will monitor how long materials have been in stock in order to prevent the quality of a label from being compromised.

To ensure quality labels, we recommend following our design requirements for label printing and using the appropriate design software. You can download our specs sheet to keep or give to your label designer.

Yes, we can print an Amazon barcode on labels, all you need to do is provide it to us. Fulfillment by Amazon (FBA) uses barcodes to identify and track inventory throughout the fulfillment process. Each item you send to an Amazon fulfillment center requires a barcode.

There are two kinds of barcodes that you can use to identify your products:

By default, seller accounts are set by default to use the manufacturer barcode to track eligible inventory throughout the Amazon fulfillment process. Sellers can change this default barcode preference at any time. Sellers can change their barcode preference for each offer they create, as well as, their barcode preference for a product when they change a listing from Fulfilled by Merchant to Fulfilled by Amazon.

If you won’t be using manufacturer barcodes to track products, then you will be required to use Amazon barcodes. You can print the Amazon barcodes on your own with a thermal or laser printer or a label company like us can print them for you. The Amazon barcodes are available in your seller account. FBA also offers a label service that will print and apply the barcodes for a per-item fee. Visit Amazon’s Seller Central to learn how to use an Amazon barcode to track inventory.

These labels came out fantastic! I couldn’t be more pleased with the way my product looks wearing them.

Posted 1 months ago

Great service, product and people!

Posted 1 months ago

The Consolidated Label Co is easy to work with. As a business, we’ve used their labels repeatedly and keep going back to them based on the quality of labels provided and the outstanding service.

Posted 2 months ago

These labels came out fantastic! I couldn’t be more pleased with the way my product looks wearing them.

Posted 2 months ago

Bernice was absoluetly fabulous to work with. So helpful.

Posted 3 months ago

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Posted 3 months ago

Leading custom packaging and printing solution supplier in China for all of your needs.